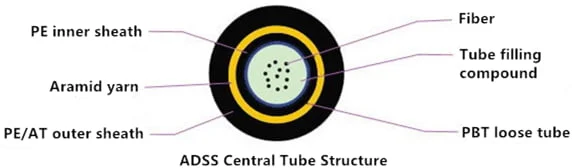

The structure of ADSS cable can be divided into two categories—central tube structure and stranded structure. In a central tube design, the fibers are placed in a PBT loose tube filled with water-blocking material within a certain length. Then they are wrapped with aramid yarn according to the desired tensile strength and extruded with PE (≤110KV electric field strength) or AT (≥100KV electric field strength) sheath. This structure features with small diameter and light weight but has limited lengths.

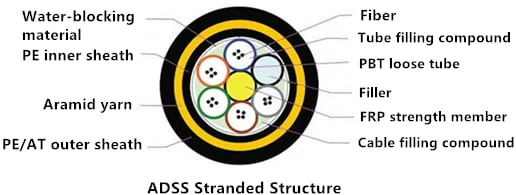

In a stranded structure design, the inner optical fibers and water-blocking grease are added into the fiber loose tube, and different loose tubes are wound around the central reinforcement (usually FRP). The rest parts are basically similar to the central tube structure. This type is able to obtain longer fiber lengths. Although the diameter and weight are relatively big, ADSS cables with this structure are better to be deployed for large span applications.

The construction quality of the All-Dielectric Self-Supporting (ADSS) cable and the quality of the optical cable have a great influence on the operation of the optical cable. Therefore, the following points are worth noting.

(1) Optical cable visual inspection: After receiving the optical cable, the user should check the cable reel and the outer optical cable in time to ensure that the received optical cable is not damaged; check whether the center hole of the cable reel has damaged the outer sheath of the optical cable or hindered the winding and unwinding of the optical cable of obstacles.

(2) Quantity inspection: Check the total quantity of optical cables and whether the length of each cable is consistent with the contract requirements.

(3) Quality inspection: use an optical time domain reflectometer (OTDR) to check whether the optical cable is damaged during transportation, and the data obtained from the inspection can be used for comparison with the acceptance inspection data after installation, and can be used as part of the data record, which is helpful Emergency repair work in the future.

(4) Inspection of fittings for installation: Check the type and quantity of fittings required for installation. If they do not meet the requirements of the contract, contact the supplier immediately and solve them properly before actual construction.

Characteristics of ADSS fiber optic cable:

1. ADSS cable has a strong ability to withstand extreme weather (gale, ice, etc.).

2. ADSS cable has a certain degree of pressure resistance and can withstand the greater grip of the strain clamp.

3. The outer sheath of ADSS cable is AT or PE material. PE sheath, ordinary polyethylene sheath, used for power lines below 110KV. AT sheath, anti-tracking sheath, used for power lines above 110KV. Running in a strong electric field, ADSS has the problem of electric corrosion. ADSS cables use different sheaths in different power lines. The most common ADSS sheaths are two types: PE sheath and AT sheath. PE sheath: ordinary polyethylene sheath. For power lines below 110KV. AT Sheath: Anti-tracking sheath. For power lines above 110KV.

Hunan GL Technology Co., Ltd as a 19 years industrial experience fiber optic cable in China, we can customize ADSS fiber cable from 2-288 core, Single or double jackets design, span range from 50m to 1300m long, if you need more information obout our adss cable price, structure, or specification, or test, we can support you!